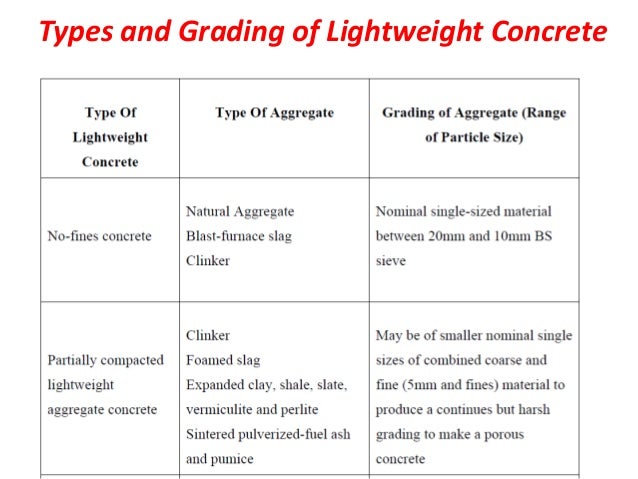

Concrete which uses lightweight aggregates may consist of lightweight aggregates are used in ordinary concrete of coarse aggregate and sand clay.

Cellular lightweight concrete slideshare.

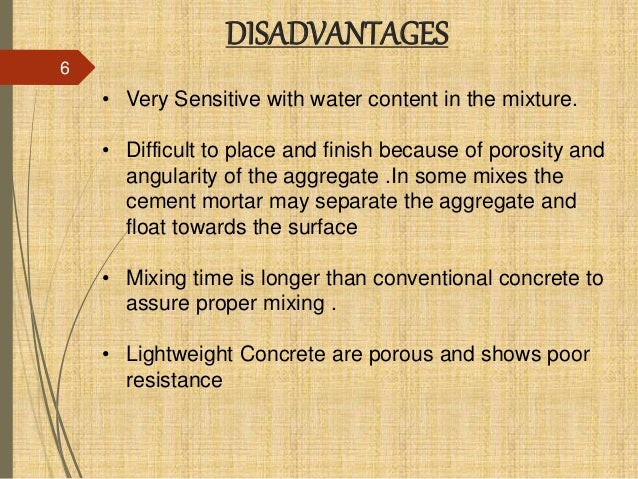

Although there are a number of lightweight cementitious materials the key differentiating factor between cellular concrete and other lightweight cementitious materials is the use of externally generated foam to reduce the density.

These air voids are established in the material via the introduction of either a protein based or synthetic based foaming.

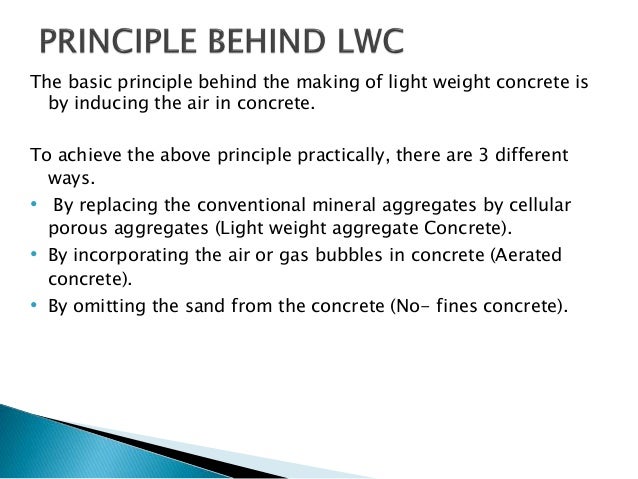

By omitting the sand from the concrete no fines concrete.

Cellular concrete is a mixture of cement water and preformed foam.

Clc is an air cured lightweight concrete with fly ash as a major ingredient that can be produced at large project sites just like traditional concrete utilising equipment and moulds normally used for traditional concreting.

To achieve the above principle practically there are 3 different ways.

The purpose of the foam is to supply a mechanism by which a relatively high proportion of stable air voids can be induced into the mixture and produce a cellular or porous solid upon curing of the mixture.

Lightweight cellular concrete lcc contains type i ii v portland cement water and a preformed foam.

By replacing the conventional aggregates by cellular porous aggregates light weight agg.

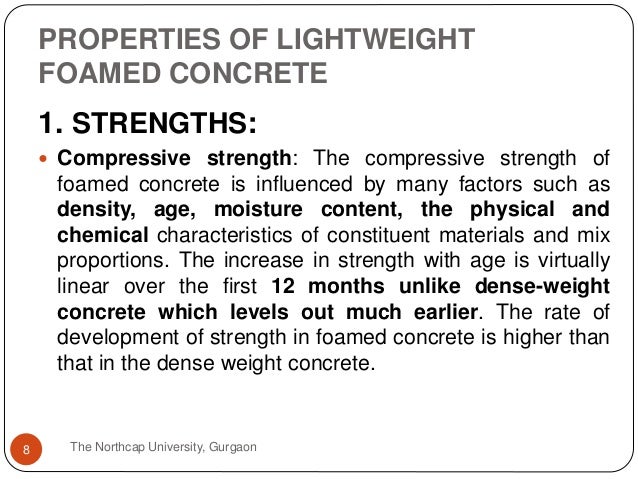

In cellular lightweight concrete the density can be controlled by the introduction of gas or foam by foam generator.

Clc blocks cellular light weight concrete blocks are made of cellular light weight concrete clc or foam concrete.

Density of this concrete is considerably low 300kg m3 to 1850kg m3 when compared to normal concrete.

Cellular concrete may go by other names including foam cement foamed concrete or lightweight flowable fill.

It was a pleasure working with the crews onsite and the superintendent was a key part in the success of the project by helping to make the schedule work with bad weather conditions.

By incorporating the air or gas bubbles in concrete aerated concrete.

The foam looks like shaving cream and is varied in quantity to control the unit weight of the cellular concrete.

When cellular concrete hardens it has an oven dry density of 50 lb ft3 8 t m3 or less.

Lcc lightweight cellular concrete is an excellent product works well for the application.

Cell crete has a very professional staff and scheduling was very easy.

Cellular light weight concrete clc is a light weight concrete that is produced by mixing cement and flyash slurry with pre formed foam.